Process Air Coolers

ComEnCo manufactures direct and indirect fired air heaters heating re-circulation air for automotive paint curing ovens. Chilled water or DX coil air cooler are used for cooling chamber in automotive paint shop. The heater and cooler design and component selections are met with automotive specification.

Burner capacity of 1,000,000 to 4,500,000 degrees.

Process air outlet temperature reaches 300 to 600 degrees

Process air outlet temperature reaches 300 to 600 degrees

Designed For High Thermal Efficiency

Automotive Paint Curing Oven Heaters and Coolers burn natural gas and propane through position proportional controls in the combustion control system and through flame safeguard relay in the burner management system.

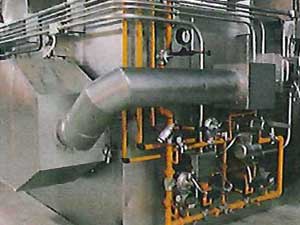

ComEnCo uses Automotive Paint Curing Oven Heaters and Coolers model series CIF and CF with a burner capacity of 1,000,000 to 4,500,000 degrees. The process air outlet temperature reaches 300 to 600 degrees with process airflow reaching 7,000 to 70,000 ACFM. This product has an indirect fired heater flue gas temperature reaching 700 degrees and an indirect fired heater thermal efficiency of 80 percent. These heaters and coolers have an indoor installation location and are used in body e-coat, primer, top coat oven, bumper top coat, fascia and dry off oven.

The features of this ComEnCo product are designed for high thermal efficiency and low resistance with a compact molecular design. Automotive Paint Curing Oven Heaters and Coolers have a simple control system with low maintenances and proven technologies leaving clean supply air.

Specifications

Model Number: Series CIF, CF

Burner Capacity: 1,000,000 to 4,500,000 Btu/hr

Process air outlet temperature: 300 to 600 degrees

Process airflow: 7,000 to 70,000 ACFM

Indirect fired heater flue gas temperature: 700 Degrees

Indirect fired heater thermal efficiency: 80%

Air Filter: High Temperature, high efficiency air filter

Installation location: Indoor

Burner Fuel: Natural gas, Propane

Combustion Control System: Position proportional control

Burner management system: Flame safeguard relay

Uses: Body E-coat, primer, top coat oven, Bumper top coat, fascia, dry-off oven

Unique Features: Compact modular design, high thermal efficiency and low resistance, simple control system, low maintenances proven technologies, clean supply air

Request A Quote

ComEnCo offers superior quality and advanced technology by in-house Engineers. Our dedicated working team perseveres to provide reliable equipment. Our in-house service technicians supply fast and on time start up services for our equipment. ComEnCo’s strong R&D continually looks for new cutting edge designs and technology for new products.