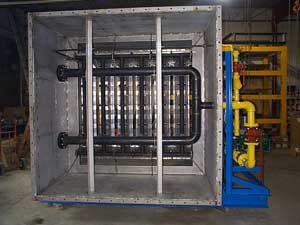

Process Air Heaters

ComEnCo manufactures direct and indirect air heaters heating fresh air or process air for industrial dryers. A burner management system and a combustion control system are used to maintain low nitrogen oxide and carbon dioxide emissions which are major environmental concerns.

The burner management system has a flame safeguard relay with the first out annunciator. The combustion control system allows a radio control and position proposition control to meter air and fuel flow. The low emission air heaters can be installed both indoors and outdoors.

Thermal efficiency 90% - 95%

Install indoor and outdoor

10,000,000 to 15,000,000 Btu/hr.

Request A Quote

ComEnCo offers superior quality and advanced technology by in-house Engineers. Our dedicated working team perseveres to provide reliable equipment. Our in-house service technicians supply fast and on time start up services for our equipment. ComEnCo’s strong R&D continually looks for new cutting edge designs and technology for new products.

High Burner Capacity & Thermal Efficiency

ComEnCo uses the low emission air heaters is series AH with a burner capacity of 10,000,000 to 15,000,000 Btu/hr. The temperature of the process air outlet is 600 to 1000 degrees with a process airflow of 150,000 to 400,000 ACFM. The heaters feature an indirect fired heater flue gas temperature of 150 to 180 degrees and a thermal efficiency of 90 percent to 95 percent. They produce emissions of NOx at 0.01 to 0.05 lb/MMBtu/hr as well as emissions of CO from 0 to 0.0075 lb/MMBtu/hr. The heaters burn natural gas, propane, butane, hydrogen, biogas and number 2 and number 6 oil.

The low emission air heaters have high burner capacity, high thermal efficiency, low emission and a safe and state of the art control system.

Specifications

Model Number: Series AH

Burner Capacity: 10,000, 000 to 15,000, 000 Btu/hr

Process air outlet temperature: 600 to 1000 degrees

Process airflow: 150,000 to 400,000 ACFM

Indirect fired heater flue gas temperature: 150 to 1800 degrees

Indirect fired heater thermal efficiency: 90% to 95%

NOx Emissions: 0.01 to 0.05 lb/MMBtu/hr

CO Emission: 0 to 0.075 lb/MMBtu/hr

Installation location: Outdoor and indoor

Burner Fuel: Natural gas, Propane, Butane, Hydrogen, Biogas, #2 to #6 oil

Combustion Control System: Air and fuel mass flow metering radio control. Position proportional control.

Burner management system: Flame safeguard relay with first out annunciator

Uses: Dryer in ethanol producing, tissue paper, gypsum board, food, chemical and any industry process industry.

Unique Features: High burner capacity, high thermal efficiency, low emission and safe and state of the art control system.